DURABILITY. SUSTAINABILITY. RELIABILITY.

Durability. Sustainability. Reliability.

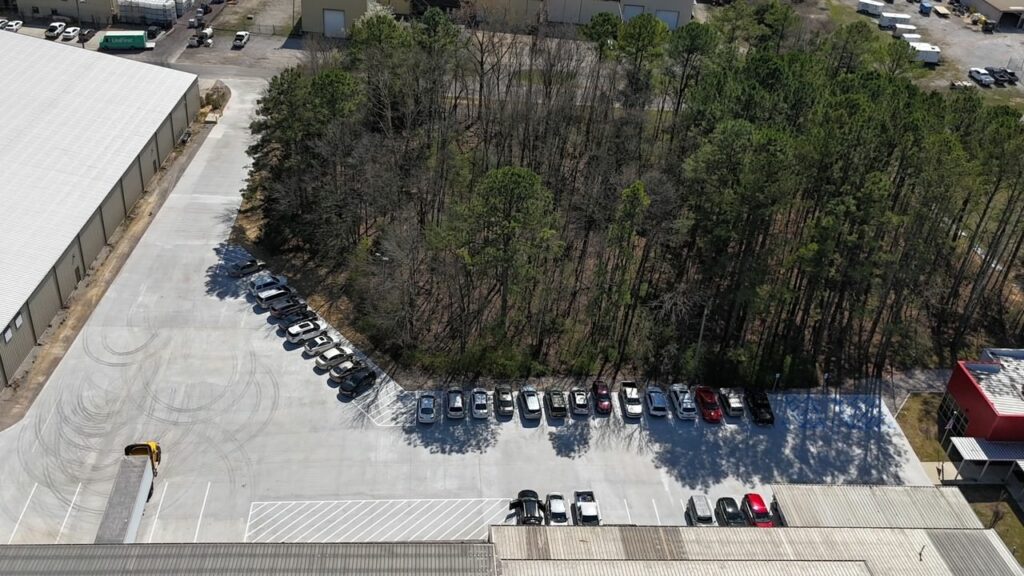

FullForce provides innovative and sustainable engineered concrete systems.

We create constructable solutions and form lasting relationships with our industry partners.

At FullForce, we’re committed to sustainable construction solutions. Our products deliver innovative, eco-friendly solutions for our industry partners. We prioritize transparency about the environmental impact of construction materials and believe our industry partners should be empowered to make informed design choices that help reduce carbon footprints. This commitment to sustainability extends across all ABC Polymer brands.

What are EPDs?

Environmental Product Declarations (EPDs) are third-party verified documents that outline a product’s environmental impact throughout its life cycle. We conducted a life cycle assessment to develop EPDs, giving our customers clear information about the environmental performance of our products.

Sustainability Benefits of Fiber Reinforcement:

Cuts Transportation Emissions

-

Lightweight packaging and fewer truckloads compared to bulky steel deliveries

-

Supports more efficient logistics and reduced jobsite traffic

Eliminates On-Site Waste

-

No cutting or bending required—fibers are mixed directly into the concrete

-

Minimizes scrap material and cleanup

Speeds Up Construction

-

Faster placement reduces equipment run time and on-site energy use

-

Fewer crew hours mean lower jobsite emissions overall

Enhances Concrete Durability

-

Controls cracking and improves long-term performance

-

Extends service life of structures, reducing the need for repairs or replacements

Supports Green Building Goals

-

Contributes to LEED credits and other sustainable building certifications

-

Aligns with low-carbon construction initiatives across the industry

Less Embodied Carbon in Your Project

-

Overall reduction in embodied carbon by replacing or reducing traditional reinforcement

-

A smarter approach for meeting sustainability benchmarks

Our EPDs can contribute to green building certifications like LEED and support carbon reduction programs. Want to learn more? Contact your local sales manager for details on our EPDs and sustainability efforts.

Cuts Transportation Emissions

-

Lightweight packaging and fewer truckloads compared to bulky steel deliveries

-

Supports more efficient logistics and reduced jobsite traffic

Eliminates On-Site Waste

-

No cutting or bending required—fibers are mixed directly into the concrete

-

Minimizes scrap material and cleanup

Speeds Up Construction

-

Faster placement reduces equipment run time and on-site energy use

-

Fewer crew hours mean lower jobsite emissions overall

Enhances Concrete Durability

-

Controls cracking and improves long-term performance

-

Extends service life of structures, reducing the need for repairs or replacements

Supports Green Building Goals

-

Contributes to LEED credits and other sustainable building certifications

-

Aligns with low-carbon construction initiatives across the industry

Less Embodied Carbon in Your Project

-

Overall reduction in embodied carbon by replacing or reducing traditional reinforcement

-

A smarter approach for meeting sustainability benchmarks